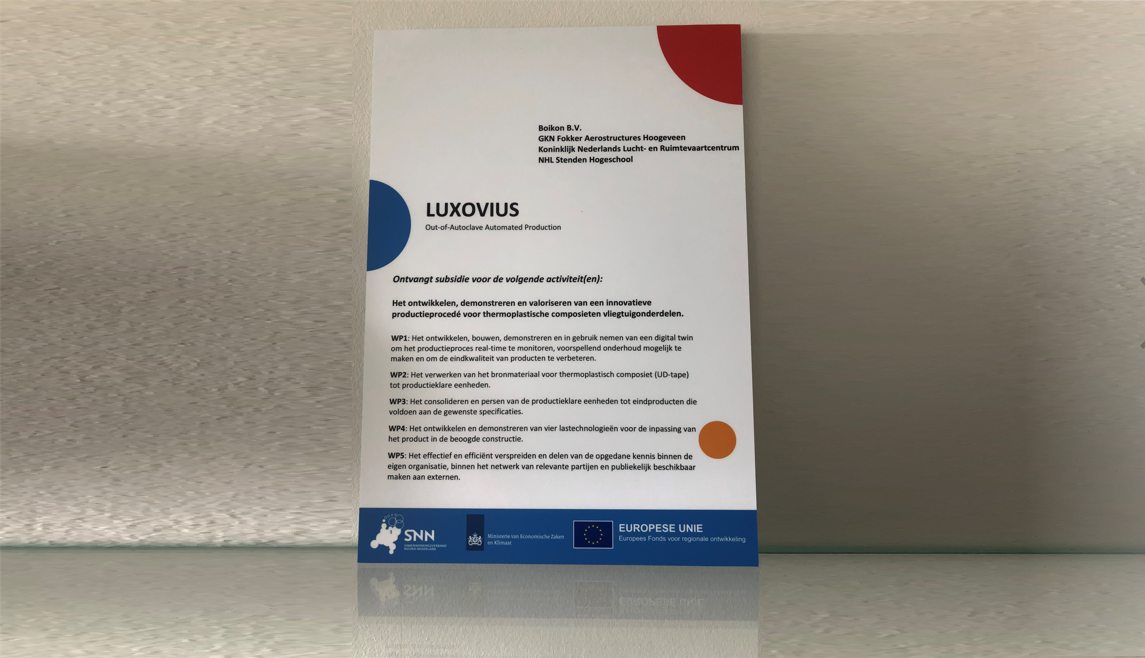

Optimization and sustainability

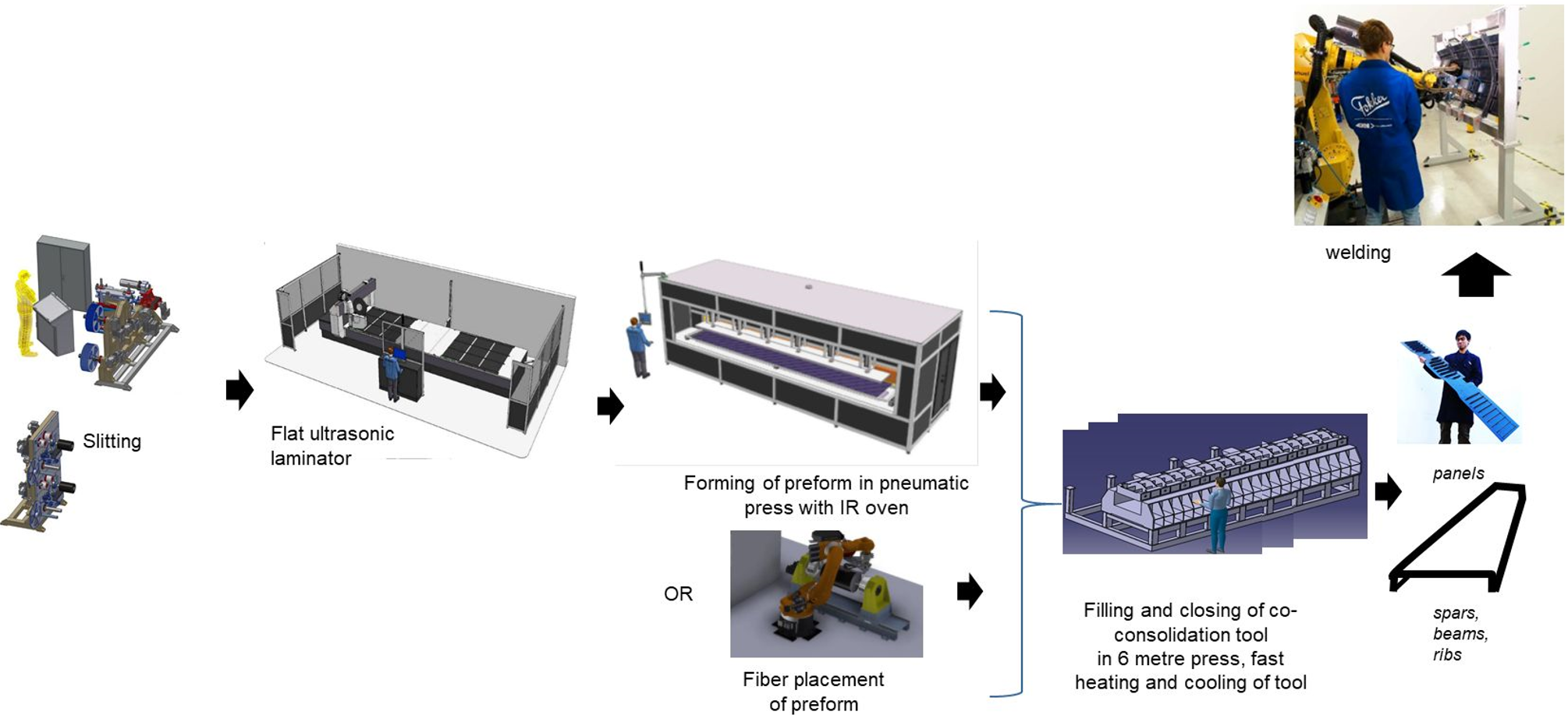

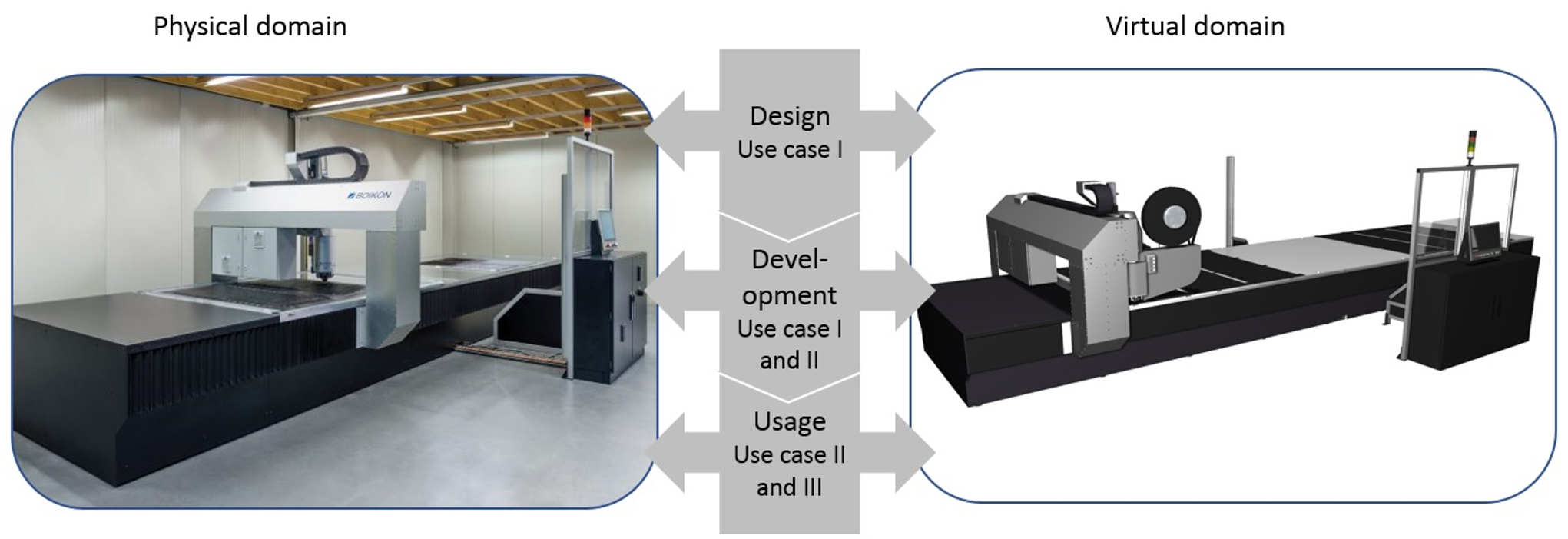

By combining a number of steps in the process in an innovative way, the partners in the project want to ensure a shorter lead time, lower CO2 emissions and significant reductions in energy consumption. In addition, lighter aircraft emit less CO2 and fuel consumption is reduced. The Luxovius project optimizes aircraft production and makes flying more sustainable.