FALKO: technology that is (literally) cutting-edge

Working with thermoplastic composites is an expensive and precise job. Expensive, because you want to be sure that you are working with high-quality and more durable materials when you are producing semi-finished products that will end up in an airplane (or any other place where you never want to skimp on safety). Accurate, because everything has to fit together seamlessly and every discarded piece is one too many.

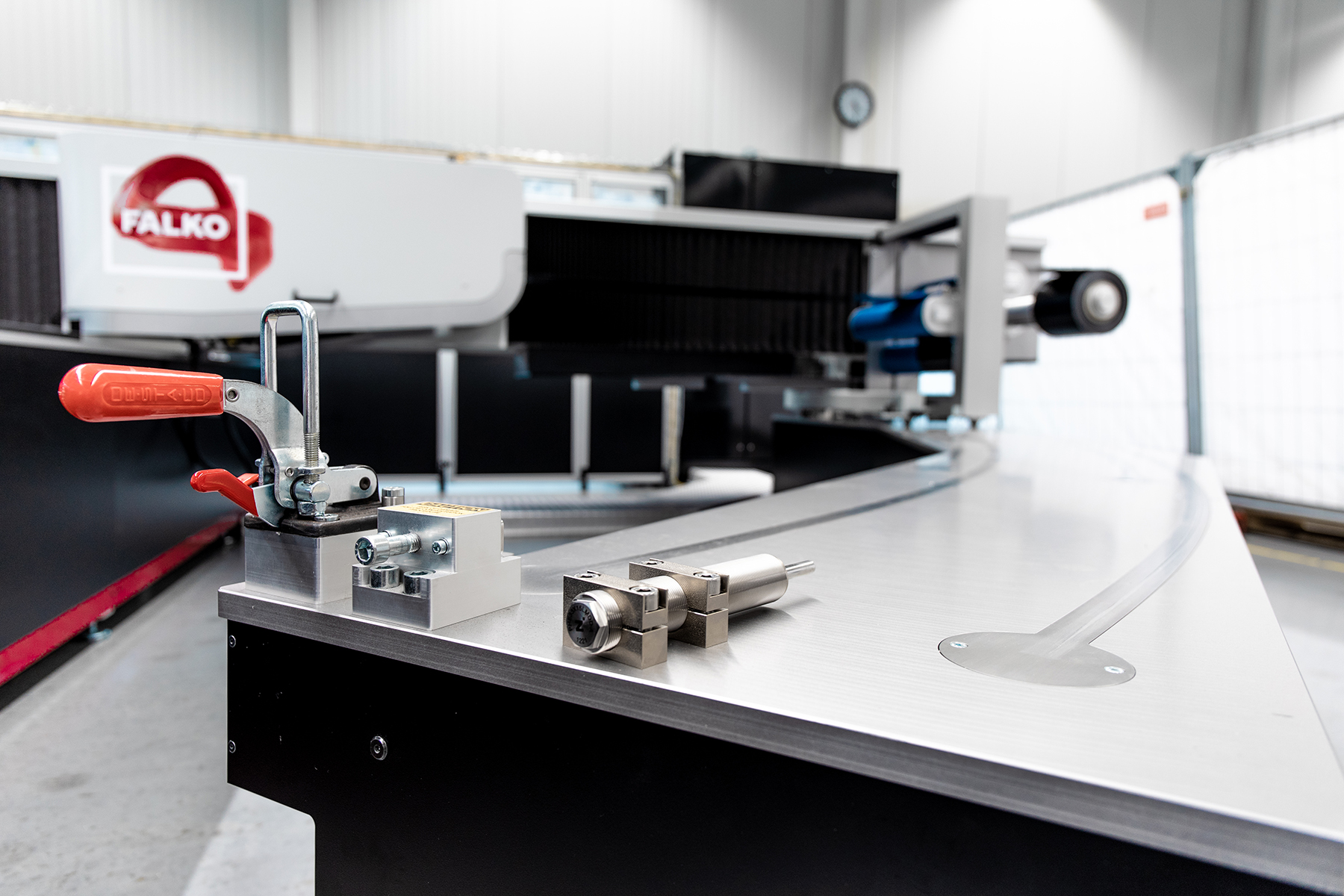

That's why FALKO works with slitting and tapelaying techniques that work to an accuracy of 50 micrometers, or one-twentieth of a millimeter. To illustrate: that is half as thick as a sheet of newspaper! This is important not only to ensure that the end product exactly meets the specifications, but also to avoid being left with residual material at the end of the production process that can no longer be reused.

The core of tapelaying is that different strips of composite are laid on top of each other at different angles and - in FALKO's case - welded together using ultrasonic welding technology. In the early stages of the technology, this often meant that jagged edges remained on either side of each semi-finished product produced. Small edges indeed, but when you can produce up to 450m2 per hour like the FALKO, it all adds up quickly. And with material that can cost a few hundred euros per kilo, it can quickly become an expensive business.

So the BOIKON technicians went back to the drawing board. Drawing, fine-tuning, testing, reprogramming... until a production method emerged that could work with strips at an angle, but which did not leave any jagged edges afterwards. In short: working more sustainably, more efficiently and more cheaply by thinking just a bit longer, and not by sitting back satisfied. That is what makes BOIKON, BOIKON and why FALKO is the perfect solution for creating superior lightweight materials. For aerospace and wind energy, but also simply for your tennis racket or field hockey stick. Without serrations.

Want to know more? Read all about it at falko-technologies.nl